The LW9/WSDB Foam Makers are integrated systems providing NFPA 11 “Type II” foam application to the rim seal area of open floating roof tanks. It allows installation without taking the tank out of service. The foam makers are designed to meter foam flow, then gently expand and deliver foam solution directly onto the seal area surface of flammable or combustible liquids.

Foam solution supply piping to the system can either be connected to a “fixed” foam storage and proportioning system, or tied into a dry pipe, “semi-fixed” piping network, which receives and delivers foam solution from a mobile fire apparatus such as a fire truck.

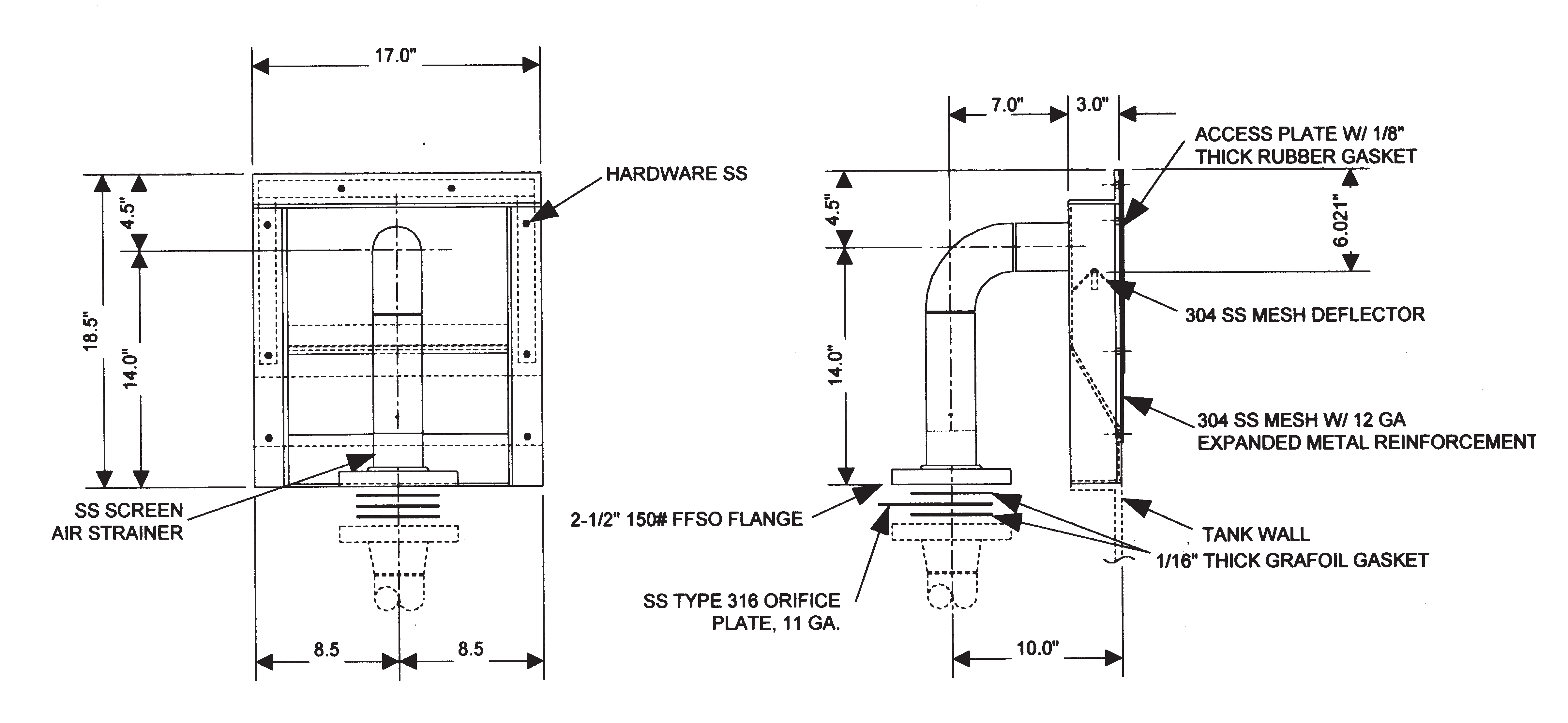

In operation, foam solution passes through an orifice plate which is sized to deliver the required flow rate at a specific inlet pressure. The metered flow of foam solution enters the interior of the discharge board, where additional aeration occurs as it impacts the deflector plates and passes through a wired mesh discharge opening.

Constructed of galvanized carbon steel, with 304 stainless steel mesh screen and trim, the entire unit can be installed to the top of the storage tank shell without the need for welding, or any “hot work” by utilizing heavy duty galvanized mounting clamps secured with stainless steel machine bolts and jam nuts.

Specifications

| Operating Inlet Pressure | 75 -125 psi (5.2 – 8.6 bars) |

| Flow Range | 25 -100 gpm (95 – 379 Lpm) |

| K-Factor | 2.5 -10.0 |

| Material Construction |

Piping and body – Galvanized carbon steel Wire Mesh Screen and Defector Trim – Stainless steel |

Ordering Information

| Part Number | Description |

|---|---|

| 10980 | LW9/WSDB Foam Maker, Red Epoxy finish |

| 14151 | Orifice plate for LW9/WSDB, stainless steel, cut to customer specification |